Jan 19, 2022

An update on our anode copper foil product & facility

Read post

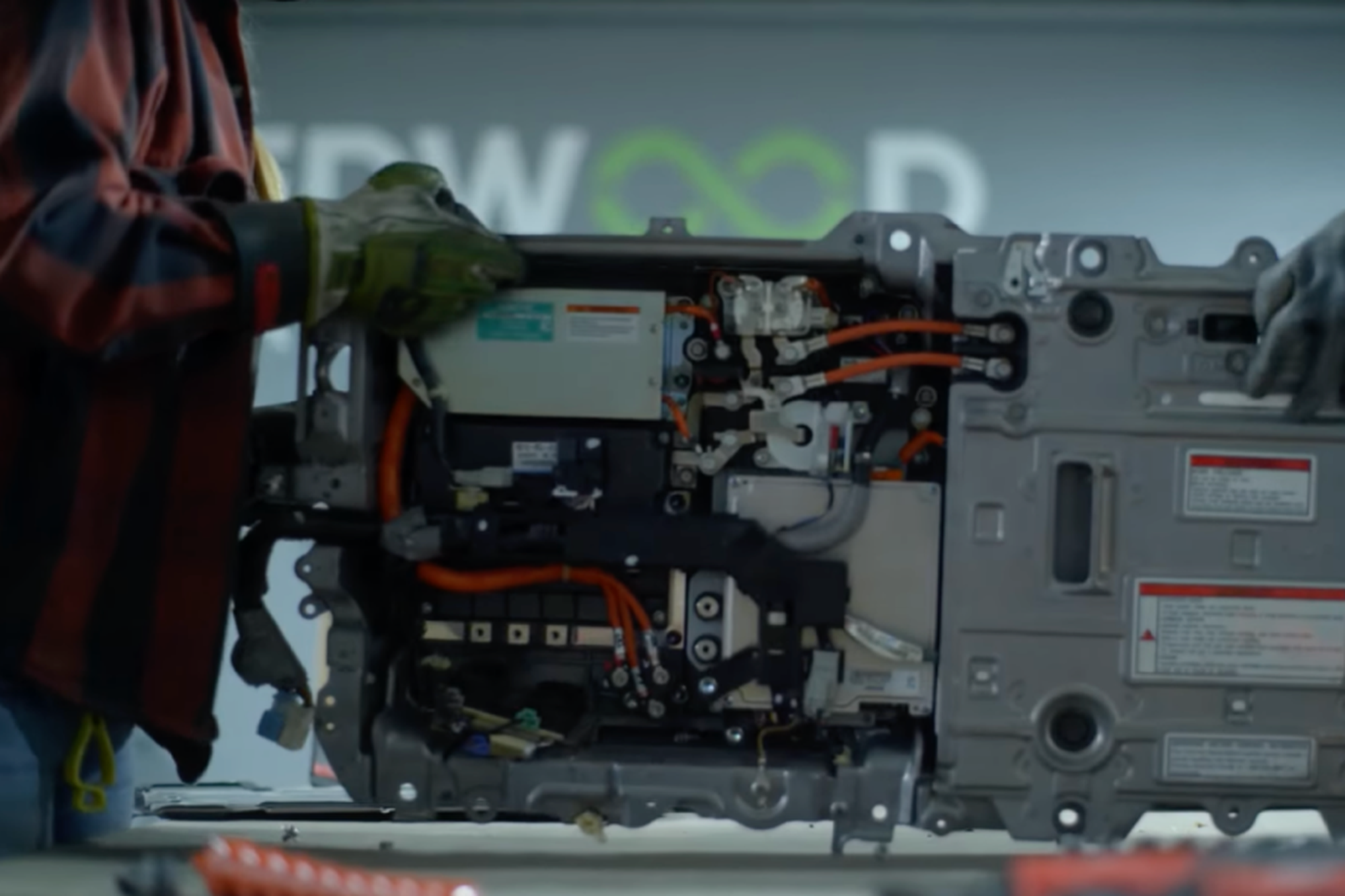

Redwood’s mission is to create a circular supply chain for batteries and help partners across the electric vehicle and clean energy industries with pathways, processes, and technologies to recycle and remanufacture lithium-ion batteries. Today we announce that we'll be working with Ford Motor Company to create a closed loop for battery recycling and a domestic supply chain for critical battery materials.

Redwood's existing partnerships span a broad range; from working with battery manufacturers to recycle production scrap to teaming up with automakers to process end of life EVs, and soon, to supplying anode and cathode materials back to the US supply chain. Our relationship with Ford will look at how we can uniquely span the entire battery lifecycle.

It’s been incredible to see the tide change as so many automakers commit to a fully electric future. However, we need to plan far ahead for the increased demand of materials that this transition will create. We also must manage supply chain risks carefully around lithium-ion batteries or we risk a repeat of the semiconductor production shortages causing chaos in the world today.

Additionally, we need to start planning now for the end-of-life of batteries as we ramp up to build millions of EVs that can’t be disposed of safely without a robust recycling solution. The exciting side of this problem is that the critical materials inside of a battery are essentially infinitely recyclable. Unlike gasoline, the materials are not consumed or lost in their lifetime of usage in the vehicle.

Creating a robust closed-loop battery industry solves both the environmental challenges at end of life and unlocks a huge new source of raw materials to help reduce supply chain materials shortages and pressure for increased mining.

While few automakers are thinking far ahead, Ford stands apart in their long-term strategic understanding that these complex issues present an incredible opportunity. Redwood and Ford share an understanding that to truly make electric vehicles sustainable and affordable, we need to localize the existing complex and expensive supply chain network, create pathways for end-of-life vehicles, ramp lithium-ion recycling and increase battery production, all right here in America.

The Ford and Redwood vision begins with incorporating battery recycling into Ford’s American battery production strategy, integrating recycled battery materials, both scrap from battery production and batteries at the end of their useful life, into the battery supply chain to drive down costs, environmental footprint and secure a critical battery material supply that Ford will need to continue to ramp their electric vehicle production.

But recycling is just the first step in creating a circular supply chain. We’ll be collaborating to determine how, together, we can create pathways for consumer vehicles to come off the road at the end of their life and be recycled and manufactured into battery materials to make more Ford electric vehicles.

Last week, Redwood announced plans to produce anode foils and cathode materials domestically and our intentions to ramp to 100 GWh of cathode material, enough for one million electric vehicles by 2025. As part of this relationship, we’re discussing how Redwood could supply Ford’s American battery facilities to ensure a steady, domestic source of sustainable battery materials to fuel the production of Ford electric vehicles.

To further advance these business opportunities between the companies, Ford has invested $50 million in Redwood to help us expand our manufacturing footprint.

Increasing our nation’s production of batteries and their materials through domestic recycling will serve as a key enabler to decrease the environmental footprint of U.S. manufacturing of lithium-ion batteries, decrease cost and drive-up domestic adoption of electric vehicles. The domestic production of batteries and their materials will help to secure our nation’s battery supply and usher in a new era of sustainable manufacturing in America. We’re excited to build the future of electric vehicle manufacturing with America’s original automaker.